The last few decades have seen vacuum technology evolve at a rapid pace, and one innovation stands out for its efficiency, cleanliness, and flexibility: the Dry Vacuum Pump. Used widely in industrial manufacturing and scientific research, this technology has quietly transformed how vacuum systems operate. Unlike traditional oil- or water-based systems that are prone to contamination, a Dry Vacuum Pump offers a clean and reliable solution for demanding environments.

This comprehensive guide explores the working concept of a Dry Vacuum Pump, its applications, the reasons behind its growing adoption, and its future potential.

The Essential Idea of Dry Vacuum Technology

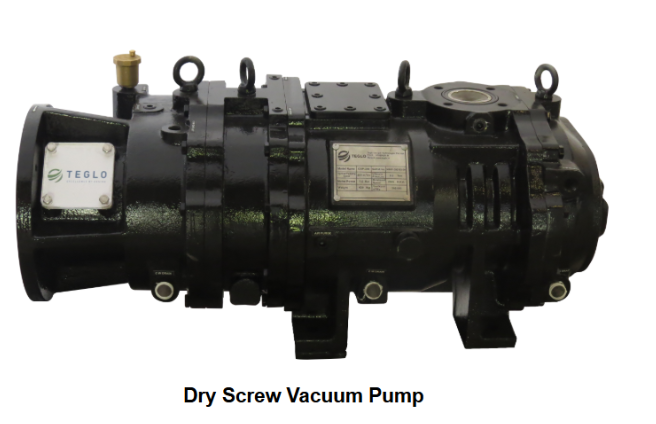

A Dry Vacuum Pump is based on a simple but powerful principle: it operates without any sealing liquids in the compression chamber. This single characteristic clearly distinguishes it from traditional vacuum systems. Since no oil or water is involved, the risk of contamination is greatly reduced.

Gas compression in a Dry Vacuum Pump is achieved purely through mechanical motion. Rotors, screws, or claws move in a highly synchronized manner, allowing gas to flow smoothly through the system and exit efficiently. The absence of fluids results in lower friction-related degradation and a much cleaner working environment.

This advanced design allows a Dry Vacuum Pump to maintain stable vacuum levels while handling a wide variety of gases, including aggressive and reactive substances.

Why Industries Are Moving Toward Dry Vacuum Pump Solutions

The increasing global emphasis on cleaner and more sustainable industrial processes has significantly accelerated the adoption of Dry Vacuum Pump systems. Environmental responsibility is a key driver. Since a Dry Vacuum Pump does not use oil, it eliminates the need for oil filtration and disposal, reducing environmental impact.

Operational reliability is another major factor. A Dry Vacuum Pump minimizes downtime by eliminating oil-related issues such as backstreaming and emulsification. Maintenance intervals are longer, and consistent performance is maintained over extended periods.

Industries also value the improved workplace safety associated with a Dry Vacuum Pump. The absence of oil mist or vapor emissions improves air quality and makes compliance with health and safety regulations easier.

Major Applications Where Dry Vacuum Pump Technology Excels

A Dry Vacuum Pump is highly adaptable, making it suitable for a wide range of applications.

In the semiconductor industry, ultra-clean environments are essential. A Dry Vacuum Pump ensures that sensitive components are not exposed to oil particles. In pharmaceutical manufacturing, sterility is critical, and a Dry Vacuum Pump helps keep production lines contamination-free.

Chemical processing plants rely on a Dry Vacuum Pump to safely manage corrosive or hazardous gases. Its robust internal design prevents unwanted chemical reactions inside the pump chamber.

Food packaging is another area where Dry Vacuum Pump technology plays a vital role. A clean vacuum environment helps preserve product quality and extend shelf life without introducing foreign substances.

Operational Advantages That Make Dry Vacuum Pump Systems Unique

One of the most notable advantages of a Dry Vacuum Pump is its consistent performance. With no oil to degrade or change viscosity, vacuum levels remain predictable and stable.

Energy efficiency is another significant benefit. A Dry Vacuum Pump typically consumes less power over its operational life due to reduced friction and optimized mechanical design. Many systems are compatible with variable speed drives, enabling precise energy control.

Noise reduction further enhances its appeal. Compared to traditional vacuum systems, a Dry Vacuum Pump generally operates more quietly, contributing to a more comfortable working environment.

Maintenance Simplicity and Long-Term Cost Stability

Although the initial investment in a Dry Vacuum Pump may be higher, the long-term cost benefits are substantial. Without oil changes, filter replacements, or fluid disposal, maintenance routines become simpler and less frequent.

A Dry Vacuum Pump also reduces the likelihood of unexpected shutdowns. Fewer consumables mean fewer potential failure points. Over time, this reliability translates into lower operational costs and improved productivity.

Spare parts typically last longer as well. Since internal components are not exposed to contaminated fluids, wear and tear is significantly reduced.

Comparing Dry Vacuum Pump Systems with Traditional Alternatives

Traditional vacuum systems often rely on oil-sealed mechanisms. While effective, these systems introduce complexity. Oil contamination, vapor backflow, and frequent servicing can interrupt operations.

In contrast, a Dry Vacuum Pump eliminates these challenges entirely. Its clean compression chamber ensures that exhaust gases remain uncontaminated, which is especially important for sensitive processes.

Another key difference is flexibility. A Dry Vacuum Pump can handle varying loads and diverse gas compositions without compromising performance.

Environmental and Regulatory Benefits of Dry Vacuum Pump Use

Environmental regulations are becoming increasingly strict worldwide. A Dry Vacuum Pump aligns well with modern compliance requirements by eliminating oil waste and reducing emissions.

The absence of oil mist results in cleaner exhaust output. This allows facilities using a Dry Vacuum Pump to meet air quality standards without the need for additional filtration systems.

From a sustainability perspective, a Dry Vacuum Pump supports long-term environmental goals by minimizing hazardous waste and reducing resource consumption.

Technological Advancements Driving Dry Vacuum Pump Evolution

Continuous innovation is shaping the future of Dry Vacuum Pump design. Advanced materials are improving resistance to heat and corrosion, enabling operation under more extreme conditions.

Smart monitoring technologies are also gaining traction. Sensors integrated into a Dry Vacuum Pump can track temperature, vibration, and pressure in real time. This data supports predictive maintenance and further reduces downtime.

Digital integration allows a Dry Vacuum Pump to function seamlessly within automated systems, supporting modern manufacturing environments that rely on precision and data-driven control.

Choosing the Right Dry Vacuum Pump for Specific Requirements

Selecting the appropriate Dry Vacuum Pump requires a clear understanding of process needs. Factors such as required vacuum level, gas composition, operating temperature, and duty cycle all play an important role.

Correct sizing is essential for efficiency. An undersized Dry Vacuum Pump may struggle to meet performance demands, while an oversized unit may waste energy.

Reviewing technical specifications and performance curves helps ensure that the chosen Dry Vacuum Pump delivers optimal results for its intended application.

Future Outlook: The Growing Importance of Dry Vacuum Pump Technology

As industries continue to modernize, the demand for clean and efficient vacuum solutions will rise. A Dry Vacuum Pump is well positioned to meet these evolving requirements.

Advances in automation, sustainability, and materials science will further enhance Dry Vacuum Pump performance. Emerging sectors such as advanced electronics and renewable energy manufacturing are also driving increased adoption.

The versatility and reliability of a Dry Vacuum Pump make it a cornerstone of future vacuum system design.

Conclusion: Why Dry Vacuum Pump Systems Represent the Future

The rise of the Dry Vacuum Pump reflects a broader shift toward cleaner, smarter, and more efficient industrial solutions. By eliminating oil, reducing maintenance requirements, and improving reliability, a Dry Vacuum Pump offers clear advantages across a wide range of applications.

From environmental compliance to operational efficiency, the benefits of a Dry Vacuum Pump extend far beyond basic vacuum generation. As technology continues to advance, its role will become even more central in shaping modern production processes.

For organizations seeking long-term value, consistent performance, and a cleaner operating environment, a Dry Vacuum Pump represents a forward-looking solution that meets both current and future demands.